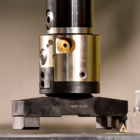

A boring bar, which is typically cylindrical in shape and has a single-point cutting tool at one end, is used to expand the interior diameter of a hole that has previously been drilled so that it meets the required specification. However depending on their geometry, cutting heads, materials used, and other aspects that affect the boring process, numerous varieties of boring bars are available to suit different purposes. For your specific application, it’s crucial to be able to select the sort of boring bar that has sufficient rigidity to withstand the force created during the cutting process. Also, the kind of setup you have makes a significant impact.

The type of bar you use

Based on their construction, structure, and material, boring bars can be classified. The strength of the boring bar to withstand powerful cutting forces with little vibration depends on the type of boring bar. Steel boring bars, carbide boring bars, and damping bars are the most often used boring bars.

- The most common varieties of bars are made of steel since they are less expensive and have good machining capabilities. These bars, however, are less rigid and more susceptible to vibrations, which in turn impact the cut quality. For applications where minimal cost is valued over great precision, these bars are advised. In general, these bars are appropriate for tasks where a diameter to drilling length ratio of 1:4 is feasible.

- As carbide bars are the most robust bars, they can be used with a smaller diameter, allowing for more chip evacuation clearance. Regardless of the associated expenses, these bars are favoured in industrial applications where high accuracy and hard materials need to be machined. A maximum diameter to length ratio of 1:8 is made achievable by these bars, however a diameter larger than 1 inch is impractical due to the high cost.

- When cutting speeds are compromised or when the surface finish chatters during a long-reach boring operation, damping bars are used. These bars have integrated dampening mechanisms that enable them to function as both friction and counter dampers, effectively absorbing chatter.

The initial setup

A boring bar is used to enlarge the diameter of a pre-drilled hole, however the quality of the machining depends on how it is set up. An incorrect setup could produce chatter marks along the bored hole, a poor surface finish, and vibrations throughout the machining operation. Therefore, it is important to examine hte clamping and overhanging lengths of the bar. When everything is in position, the tool post is moved, so that the boring bat’s cutting tip comes in contact with the surface to be machined, and the handwheels’ reading is set to zero. By doing this, any reading errors in determining the depth of the cut are eliminated, resulting in precise dimensions for the finished hole.

Thus, make sure your application has the appropriate setup and boring bar type. Uncertain about which boring bar you’ll require for your specific application? Get in touch with professionals like FineTech Toolings, the most reliable precision boring bars manufacturers In Bangalore, who can determine the ideal boring bars for you based on the nature of your industry and your needs.