Boring a hole requires the use of the right tools to achieve the desired characteristics of hole dimensions, position accuracy, and surface finish. The boring head is one such tool that is used to create large diameter holes when tolerances do not allow for a drill bit, or do not have a large enough drill bit or reamer. Boring heads are also used to enlarge holes, or adjust hole center-lines in certain instances.

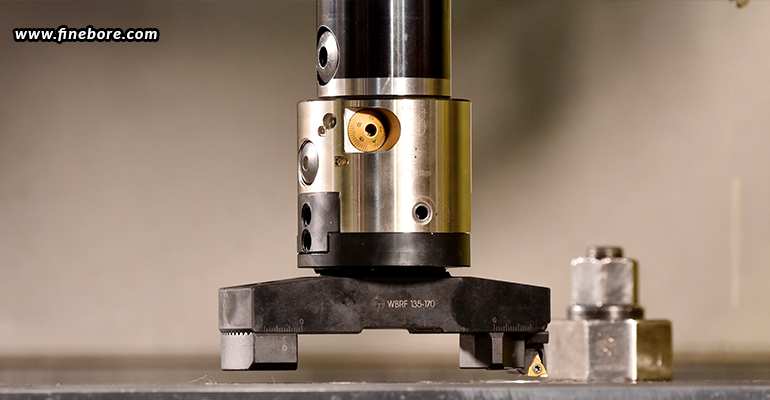

A boring head consists of three main components, namely the boring head body, the bar holder, and the dial screw. The head holds cutters in position, vertically or horizontally, to rotate and gradually remove the excess material, until the hole is at the diameter that is required. There are a number of boring head types available for boring operations, which can be chosen as per the application requirements. Because every application is different, the boring head needs to be selected as per one that matches the work to be done. You can always get in touch with expert precision boring head manufacturers In Bangalore, one like FineTech Toolings, to discuss your requirements, and have the most suitable boring head installed for your specific application. Some important aspects that are considered while choosing a boring head include the diameter range, the connection sizes, the resolution, and the balancing insert holders. Below stated are some of the most basic boring head types used.

Rough boring heads

Rough boring heads are used after a hole is created with the help of drilling or any other method, and when larger amounts of excess material are to be removed from the created hole. Such boring heads are more rigid to handle the increased depths of cut, torque, and axial forces needed to efficiently and consistently make the passes to remove the excess material.

Fine boring heads

Fine boring heads are used as the next step, when more delicate and precise removal of material is required to finish the work that is done by the rough boring head. When a lot of excess material is removed by the rough boring head, the fine boring head is then used to remove the minute amount of material left to remove, so as to achieve the final finished hole. Such boring heads are often balanced for high-speed cutting, as that is the best approach for reaching the exact specifications of a hole.

Twin cutter boring heads

These types of boring heads are used when the cutting of the hole and removal of excess material is required to be speeded up. As the name suggests, such heads include two cutters that can perform cutting, thus improving the speed otherwise involved.

Digital boring heads

Another way to speed up the process of boring is by installing a digital boring head. When done the traditional way, adjusting boring heads can be time-consuming. But, with digital boring heads, there is an LED that makes precise adjustments much easier and quicker.

Specialty boring heads

After a hole is bored, there may be additional secondary processes required by the application, which can be executed with the help of specialty boring heads like back boring heads, face grooving heads, and chamfering insert holders. Certain manufacturers cater to this requirement and manufacture specific heads with cutters at appropriate angles, so that each of these secondary operations can be done without manually moving the part, changing the tool, or adjusting the cutter angle.

Whatever your application – small, medium, or large diameter – make sure to choose the most precise tools for the highest performance and exact results. Boring tools are available in a variety of heavy-duty materials like steel, aluminium, and carbide. Make your choice depending upon what is required by your particular application.