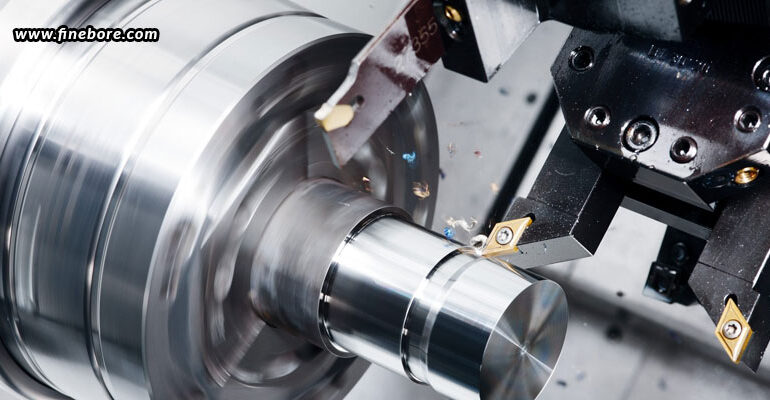

Boring is the process of enlarging a hole that has already been drilled or cast, by means of a single-point cutting tool such as a drill. Boring can be used to make tapered holes as well as increase the precision of a hole’s diameter. The process can be viewed as the internal-diameter counterpart to turning, which cuts external diameters. However, boring is somewhat more difficult than turning due to decreased tool-holding rigidity, increased clearance angle requirements (limiting the amount of support that can be given to the cutting edge), and difficulty in inspecting the finished surface (size, form, and surface roughness) due to the limitations on tooling design imposed by the fact that the workpiece largely surrounds the boring tool. Because of these factors, even though boring and turning are similar in some respects, boring is seen as a distinct branch of machining practise, distinct from turning, with its own techniques, problems, and body of knowledge.

Types of boring

Boring comes in a variety of forms. The boring bar can either be supported at one end (which works for both through holes and blind holes) or both ends (which only works if the existing hole is a through hole). Then there is backboring, which involves reaching through an existing hole and then boring on the rear side of the workpiece.

Types of boring tools

Unsatisfactory boring can occur if your boring tool permits too much vibration or chatter, if your tooling geometry requires additional passes, if you can’t modify it for the sort of component you’re working with, or if you can’t rapidly replace or sharpen your cutting edges. For this reason, you must be extremely certain when you buy a boring tool for a particular boring application. Choosing the correct boring tools will ensure increased efficiency, reduced downtime, and improved productivity levels.

For example, carbide boring bars are the perfect answer when finishing exceedingly long holes and requiring the maximum amount of rigidity. Solid carbide bars are not suggested for heavy roughing, though. Heavy metal boring bars are required for high rigidity in these situations because their dense structure and machinability provide more toughness than carbide bars. These bars are suitable for long holes as well. Similarly, you must decide whether you require fine or rough boring heads. Since they can be precisely adjusted in tiny increments to provide the necessary results, fine boring heads are ideal for completing holes with a narrow tolerance. These boring heads are available in a variety of designs; some use standard round boring bars, while others use unique insert holders. The boring head should be selected based on the application and purpose. Back boring and face grooving heads, specific heads with cutters at appropriate angles, and chamfering insert holders are other accessories that can be used. You can always approach FineTech Toolings to discuss your requirements with experts and obtain the best precision boring tools in Bangalore for both roughing and finishing applications, no matter what kind of tool you need.