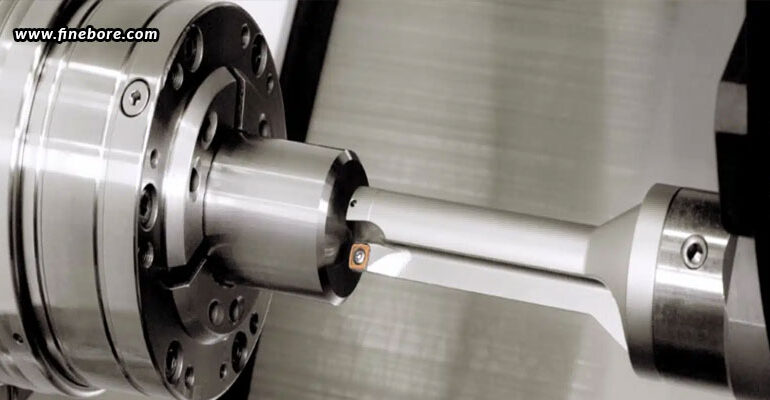

When it comes to accurately and precisely expanding holes to precise specifications, boring heads are an essential tool. The effectiveness and calibre of your job are directly impacted by the boring head’s performance, regardless of whether you’re working on complex pieces or substantial industrial components. It takes more than simply the correct tools to get the best results; careful setup, consistent upkeep, and a thorough grasp of optimization strategies are also necessary. Every stage is critical to optimizing performance, from choosing the right boring head for your particular application to adjusting cutting settings and putting cutting-edge technology into practice. Thig blog will take you through ten expert tips that will increase the accuracy, effectiveness, and lifespan of your boring heads and guarantee that your machining processes continuously yield superior results. These tips will enable you to get the most out of your boring heads, regardless of your level of experience.

-

Choose the right boring head for your application

The first step towards attaining best performance is choosing the right boring head. Consider factors like the material you’re using, the hole’s size and depth, and the level of accuracy needed. Different types of boring heads are made for different purposes; precision boring heads are perfect for maintaining strict tolerances, while modular boring heads are versatile for a variety of jobs.

-

Ensure proper setup and alignment

Precise configuration is essential for maximum efficiency. Here’s how to make sure the alignment of your boring head is correct:

- Mounting: Make that there is no play or misalignment in the mounting of the boring head to the machine spindle.

- Centering: To verify and fine-tune the boring head’s centering, use a dial indication. Reduced precision and uneven cutting might result from misalignment.

- Tool length: To reduce deflection and increase stability, keep the tool length as low as feasible.

-

Use high-quality cutting tools

The performance of your boring head is greatly affected by the cutting tool you choose. Choose sharp, well-made cutting tools that are appropriate for the material of your job. High-speed steel (HSS) tools are ideal for softer metals, while carbide and diamond-tipped tools perform exceptionally well on tougher materials. Maintaining cutting accuracy and efficiency requires routinely inspecting and replacing worn-out tools.

-

Optimize cutting parameters

For the boring head to operate as efficiently as possible, the cutting parameters (depth of cut, feed rate, and speed) must be set correctly. Here are some rules to follow:

- Speed of cutting: Depending on the material and cutting tool, adjust the spindle speed. Tool wear can result from excessive speed, and cutting efficiency might be decreased by excessive speed.

- Feed rate: Adjust the feed rate to strike a balance between surface finish and productivity. While throughput may decrease, finish can be enhanced by a slower feed rate.

- Depth of cut: To prevent excessive tool load and chatter, start with a light depth of cut and then gradually increase it.

-

Implement proper coolant and lubrication practices

Optimizing cooling and lubrication may prolong the life of tools and enhance their cutting efficiency. Make sure the coolant you choose is suitable for the material and cutting circumstances. To ensure that coolant reaches the cutting area directly, make sure the coolant nozzles are positioned appropriately. Regularly monitor and maintain coolant levels and quality to minimize overheating and reduce tool wear.

-

Minimize vibration and chatter

The precision and smoothness of your bored holes can be significantly impacted by vibration and chatter. Here are some strategies to reduce these issues:

- Stable configuration: Make sure the machine is rigidly configured and the workpiece is secured firmly.

- Tool geometry: Utilize cutting tools with geometries—such as positive rake angles and sharp cutting edges—that are intended to minimize vibration.

- Balancing: To avoid vibrations caused by imbalance, balance the boring head and cutting tool assembly.

-

Regular maintenance and inspection

Maintaining the optimal condition of your boring head requires routine inspections and maintenance. Add the following items to your calendar for maintenance:

- Cleanliness: In order to avoid debris accumulation that might impair performance, keep the boring head and cutting instruments clean.

- Lubrication: To lessen wear and friction, lubricate moving parts on a regular basis.

- Inspection: Check the boring head on a regular basis for indications of wear or damage, including loose parts or worn bearings, and replace any necessary parts.

-

Leverage advanced technology

Boring head technology has advanced to a point where it can greatly improve performance. Think about making the following investments:

- Digital boring heads: These offer accurate diameter setting with precise adjustments and easily readable digital displays.

- Automatic compensation systems: These systems maintain constant precision by automatically compensating for heat expansion and tool wear.

- Boring bars with vibration dampening: These bars include damping systems to lessen vibration and enhance surface quality.

-

Train your operators

To operate at peak efficiency, even the most powerful machinery has to be operated by qualified personnel. To make sure your operators know how to set up, run, and maintain boring heads properly, invest in their training. Your staff may stay up to speed on new methods and technology with regular training upgrades.

-

Document and analyze performance

You may find patterns and opportunities for improvement by keeping thorough records of your machining operations, including cutting parameters, tool usage, and maintenance activities. Analyze this data often in order to:

- Optimize processes: To continually increase productivity and quality, make adjustments to parameters and methods in response to performance data.

- Estimate upkeep requirements: Reduce downtime by forecasting when maintenance or tool replacement will be required using past data.

- Troubleshoot issues: By comparing current data with past records, you may quickly discover and fix performance issues.

To get the most out of your boring heads, you need to combine cautious selection, accurate setup, and continuous maintenance. You may increase the durability, precision, and efficiency of your boring heads by following the aforementioned 10 expert tips. This will raise the general productivity and calibre of your machining processes. These tactics can help you get the most of your boring head investment, regardless of your level of experience. Renowned precision boring head manufacturers in Bangalore, FineTech Toolings, provide top-notch tools that can make a big difference in achieving these ideal outcomes. Through the use of their cutting-edge technology and knowledge, you can guarantee that your machining operations are constantly of the highest calibre.