Successful Applications Of Boring Bars In Various Industries

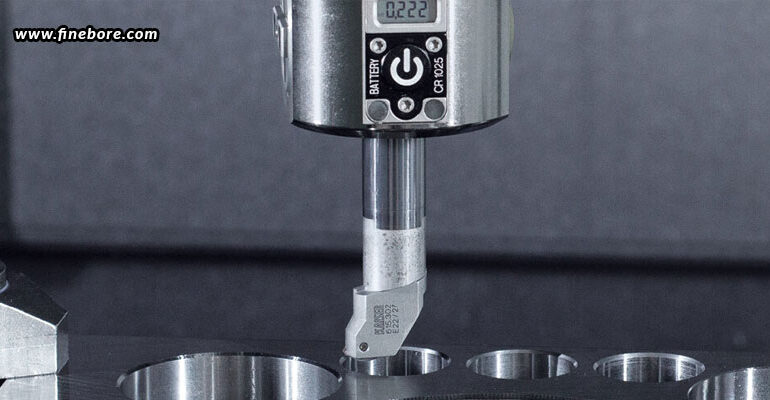

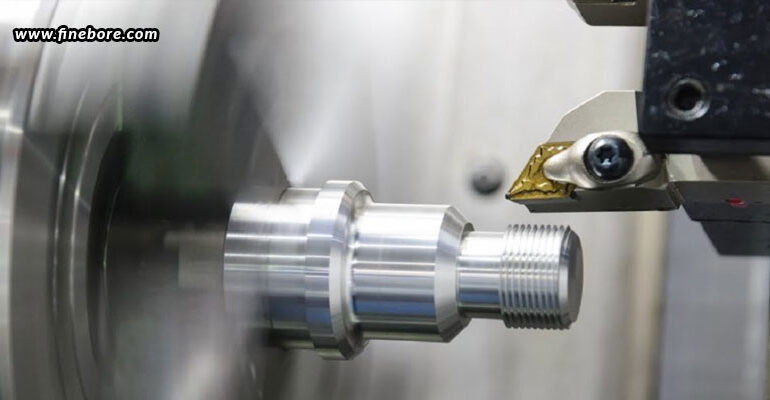

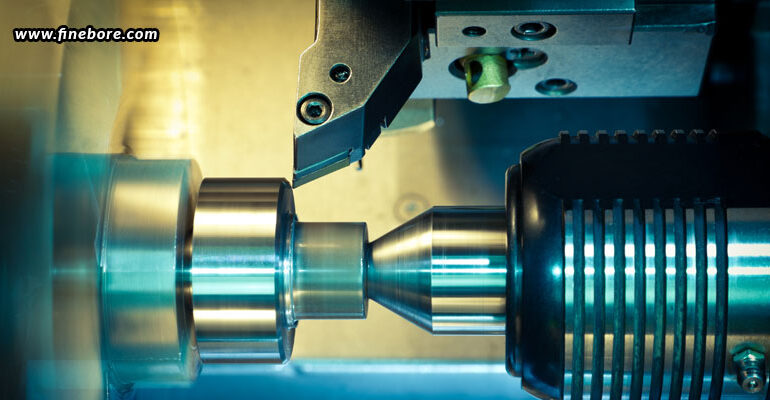

For high accuracy interior diameter machining in a variety of industries, boring bars are a necessary tool in precision machining. Their use is widespread, ranging from the automobile to the aerospace industries, where accuracy, dependability, and effectiveness are critical. This blog examines the effective uses of boring