Precision boring of complex aerospace parts requires good machines, good tools, and coolants, along with a defined repeatable process. The difference between a good aerospace part and a scrapped part can be just a few tenths of an inch on a bore, but the penalty for a scrap part can cost big bucks! This is why it is essential that every kind of scrap is eliminated in this industry.

Aerospace parts are usually made from hard metals like stainless steel, titanium, and Inconel; all of these materials being very difficult to precision bore, thus increasing the expenses involved with the process. Moreover, precision boring operations are the last processes to be executed, hence any scrap due to oversize holes means the hours invested in milling and threading before the precious boring all go in vain! In fact, the price that goes into producing such a scrap part can at times cost a company its entire monthly budget! This makes it absolutely essential for every aerospace part manufacturing company to develop improved processes to eliminate scrap at all costs.

How to develop an improved process?

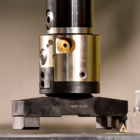

One way to achieve the right process is by first understanding how bore results vary based on tools with different lengths and inserts, with different geometries and sharpness. There are many parameters that influence the finishing process, which involve such low-machinability materials and the operation’s tight-tolerance requirements. One solution to overcome all these challenges is by manufacturing every hole with two passes, with almost no adjustment in the diameter of the cutting edge in between. The first pass if doesn’t finish the hole, a second spring pass can reach the tolerance. The spring pass removes more diameter material than the first pass.

Challenges involved with precision boring

- As mentioned above, the hard metals used to manufacture aerospace parts are very difficult to precision bore. Thus, high cutting forces are applied, which results in more heat generated at the tool tip, which leads to stringy and difficult-to-break chips. Any abrasion here can also result in tool wear.

- Another challenge here is to reasonably predict tool deflection, something that is easy with soft metals, but not with the hard metals used in the aerospace industry. When tool wear is combined with harmonics and sharper inserts, these hard metals prove to be even more difficult to precision bore. Moreover, as the length of the tool increases, the more difficult it becomes. The process involved is thus significantly much harder than with shorter softer tools.

- The third challenge is to work out a rule for how and when to adjust the boring head. This will only come with practice and prediction as to when a tool needs to be adjusted.

The above-mentioned issues are the toughest problems, and the most challenging tests one could encounter. Nevertheless, engineers are always expected to systematically and methodically approach every boring problem with a solution. After all, every hole in the aerospace industry needs to be a completed workpiece, which cannot be left undersized, cannot be bored oversized, cannot have excessive taper, and cannot have bad surface finish. You thus need the best precision boring tools in Bangalore if you’re in the aerospace industry; and that you can get when you approach Finetech Toolings, where every product is industry-specific in nature and is in conformance to international quality standards.