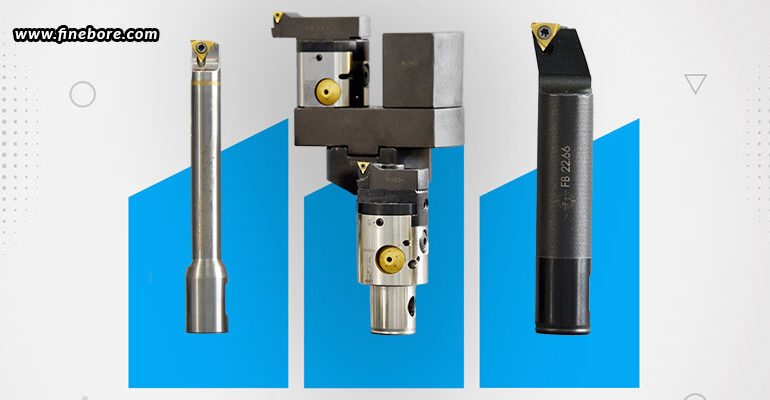

Precision boring tools are specialized cutting tools used in machining operations to produce precise holes with tight tolerances. Precision and accuracy are crucial in sectors like manufacturing, aerospace, and the automobile industry, where these instruments are frequently employed. Here are 5 basic types of precision boring tools used extensively across industries.

Boring bars

The most often used equipment for precise boring is a boring bar, which is a cylindrical metal bar with one end designed for cutting and removing material. The cutting tip, when inserted into a workpiece, can remove material and make a hole with the specified diameter and depth. Boring bars are typically made of high-speed steel, carbide, or other advanced materials such as cubic boron nitride or polycrystalline diamond. Due to their greater hardness and wear resistance, carbide and other advanced materials are suited for demanding machining applications.

Boring heads

The diameter and depth of the hole being machined can be precisely adjusted with the help of adjustable tools called boring heads. A body, a boring bar or shank, and an adjustable boring tool are the basic components of boring heads. The boring head’s body contains the mechanism for regulating the cutting diameter, and the boring bar secures the head to the machine spindle while also providing stability. The mechanism in boring heads enables accurate adjustment of the cutting diameter. To provide precise and repeatable changes, this mechanism may use micrometre dials, indexable graduations, or digital readouts.

Rough boring tools

To swiftly and effectively remove a lot of material, roughing boring tools are employed. They are made to resist greater cutting forces and have larger cutting edges. Finishing boring tools are used to produce the desired final dimensions and surface polish after roughing.

Micro boring tools

Small and complicated holes with dimensions typically ranging from a few micrometres to a few millimetres can be machined with the help of micro boring equipment. This is because in order to get precise outcomes in micro-machining applications, they need high accuracy and stability, which these micro boring tools can provide.

Twin cutter boring tools

Two cutting edges make up the unique design of twin cutter boring tools, which concurrently remove material. With this design, cutting efficiency is increased and machining time is decreased. In settings of high-volume production, twin cutter tools are frequently employed.

For best results when using precision boring tools, care must be taken in tool selection, setup, and cutting parameters. The tools must also undergo routine maintenance and inspection in order to remain accurate and effective. You can get the finest precision boring tools in Bangalore at FineTech Toolings, an ISO 9001:2015 certified company that is committed to maintaining high level of quality management systems and processes for manufacturing boring tools. We are an established company with expertise in manufacturing, supplying, and exporting a wide range of boring tools, boring bars, boring heads, and accessories. Our products are designed to meet industry-specific requirements and comply with international quality standards. You can thus rely on FineTech Toolings for reliable and precise boring solutions.