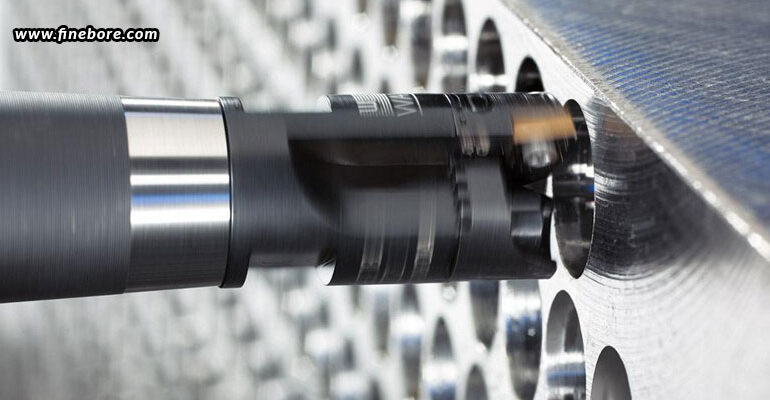

Boring bars are versatile instruments that are used in a variety of industries and machining processes to enlarge, shape, and finish internal holes or bores. The following are some typical purposes that boring bars serve.

Expanding or finishing up already existing holes

To obtain accurate size, diameter, tolerance, and surface finish, pre-drilled or pre-machined holes are frequently finished or enlarged using boring bars. To get a workpiece to the proper size and tolerance, they remove material from the inner diameter. This is especially helpful for businesses in the automotive, aerospace, and manufacturing sectors.

Creating precision bores

For cylindrical parts like engine cylinders, hydraulic cylinders, bearing housings, and valve bodies, precise, concentric, correctly proportioned bores are made using boring bars.

Internal threading

Internal threads can be cut inside bores using boring bars with threading inserts, enabling the assembly of threaded components. This is frequently done in applications where threaded holes are necessary for fasteners or threaded inserts.

Taper boring

Boring tools with adjustable heads or inserts can be used to make tapered holes or bores, which are frequently needed for applications like tool holds, machine spindles, and Morse tapers. Applications that call for a conical or tapered shape, like machining tapered seats or mating surfaces, can benefit from this.

Counterboring and countersinking

Boring bars can be used for counterboring and countersinking operations, which result in the creation of chamfers or recesses at the hole’s entry. Counterbores are often used to make room for bolt heads, screw heads, or other fastening elements. Similarly, countersinks are used to accommodate screw heads, rivets, tapered pins, and chamfering edges.

Contouring and profiling

Boring bars can be used for contouring and profiling operations to create intricate interior forms or features in a workpiece by using specialised inserts or tool geometries.

Boring of complex shapes

The internal machining of complex shapes, such as undercuts, stepped bores, or asymmetrical contouring, can be done with boring bars. In fields that demand accuracy and intricate geometry, like aerospace and automotive, this is frequently done.

Facing operations

On the inside surface of a workpiece, facing operations can be performed with boring bars. They make sure that components are properly aligned and fit together by removing material to produce a flat or smooth surface perpendicular to the hole.

Internal grooving and parting

For internal grooving and parting operations, boring bars can be fitted with specialized tooling. They are used to split an item into two pieces by cutting through it or making internal grooves in it.

Maintenance and repair tasks

Boring bars are also used in maintenance and repair tasks to restore worn-out or damaged bores to the desired dimensions by removing material from them.

These are just a few examples of the numerous functions a boring bar can serve. Boring bars can be used in several applications, depending on the workpiece’s material, size, shape, required tolerances, and machining setup. Therefore, before choosing your boring bar type, make sure to take into account all of these factors as well as the purpose you want the bar to serve. No matter what your application and purpose, you can always get the finest boring bars in Bangalore at FineTech Toolings, an ISO 9001:2015 certified company who always ensures every product to be industry specific in nature and in conformance to international quality standards.