Boring, a precision machining technique, entails enlarging or fine-tuning already-existing holes in a workpiece to improve accuracy and surface finish. It involves using a range of cutting tools to remove material from the hole’s inner diameter in order to create a hole of the required width and length. Boring guarantees that the hole’s surface is consistent and smooth, and that its dimensions adhere to strict standards. However, the world of machining is one of extreme accuracy, where each cut and each movement count. In this field, the boring head is a versatile and essential instrument that makes it possible to produce holes that are precisely the right size, and have flawless surface finishes.

The significance of boring precision

In machining, bore precision is of the utmost significance. For mechanical components to fit, align, and function properly, accurate holes are required. Even a small departure from the ideal dimensions might cause problems with alignment, reduced effectiveness, or even component failure. Precision in the boring process ensures repeatable and dependable outcomes, enabling parts to integrate easily into intricate assemblies. Furthermore, perfect boring results in smooth surface finishes that decrease friction, increase component lifespan, and improve overall performance. Boring precision has a direct impact on the quality and functionality of the finished product and is therefore a cornerstone of machining excellence in key industries like aerospace, automotive, and the medical sector, where safety and reliability are non-negotiable.

Boring head

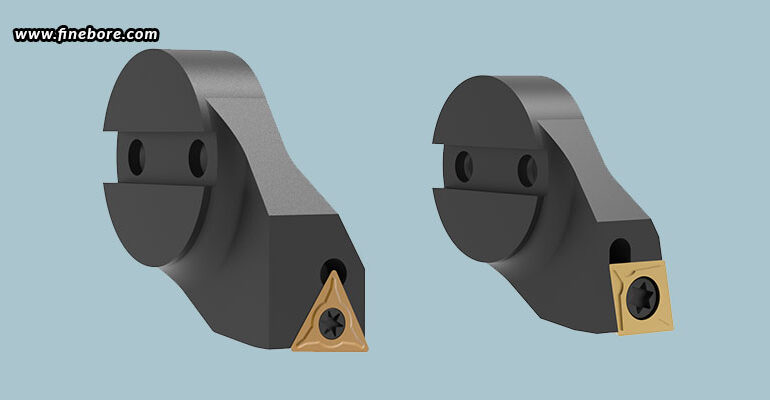

A versatile machining tool called a boring head is used to precisely enlarge or improve holes. It comprises of a spindle-mounted adjustable cutter that allows for controlled material removal from a workpiece’s interior. Boring heads are used in a variety of industries, including aerospace, automotive, and industrial, to obtain precise hole diameters, excellent surface finishes, and alignment. Boring heads provide versatility in hole size and shape due to the variety of available types and configurations. This tool is essential to contemporary precision machining techniques because of its capacity to maintain tight tolerances and flawless surface quality.

Applications of the boring head

The boring head’s main use is to produce holes with unmatched accuracy and a superior level of surface finish. It makes ensuring that holes have precise tolerances and smooth, uniform surfaces, which are essential for components that need precise fits and low friction. They also excel in precisely enlarging holes with a considerable diameter. This use is widespread in sectors like manufacturing and construction where precise hole sizing is essential for assuring appropriate component assembly and performance. Boring heads can also be used for back boring, which enlarges holes from the end, and counterboring, which makes flat-bottomed recesses. In situations when components must accommodate bolts, screws, or other fasteners without jeopardizing structural integrity, these applications are essential.

Achieving precision with the boring head

It’s essential to keep vibration and chatter under control for accurate machining. Cutting speeds and feeds that are appropriate for the tool being used, stiff setups, and proper tool selection all work to reduce these undesirable effects and provide smoother, more precise cuts. It is crucial to choose the appropriate cutting parameters, such as feed rate and cutting speed. Precision and consistency are improved by ensuring effective chip removal and reducing tool wear by balancing these characteristics with the material being machined. Additionally, efficient lubrication and cooling are necessary to minimize friction and dissipate heat during machining. Particularly, in complex or deep-hole boring operations, proper cooling extends tool life, reduces overheating, and assures dimensional accuracy. All of this is accomplished by using the proper boring head, which you can simply obtain from Finetech Toolings, one of the finest precision boring head manufacturers in Bangalore, where solutions are provided to machine even the most challenging parts, such as large diameter holes and deeper bores. With the boring products from Finetech Toolings, you may get greater rigidity and superior performance, regardless of the application or requirement.

Excellence in machining is built on precision, and the boring head is a tool that best symbolizes this quest for perfection. The boring head demonstrates its adaptability across industries by attaining perfect hole precision as well as overcoming the difficulties of large-diameter holes and elaborate shapes. The simple boring head remains a beacon of accuracy in the ever-evolving world of manufacturing, inspiring innovation and perfection in the production of machined components.