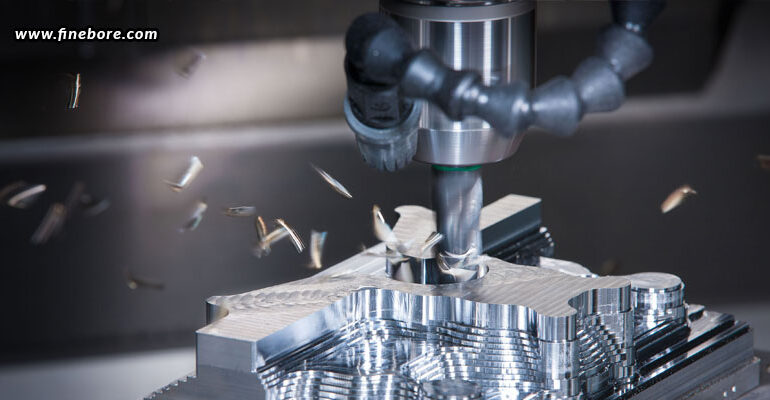

Precision boring is a vital machining procedure employed across varied sectors to accomplish outstanding precision and excellent surface finishes. This process, which is used for manufacturing vital components, guarantees close tolerances and raises the general calibre of machined parts. Precision boring contributes to the creation of high-precision components necessary for applications in aerospace, automotive, and other precision-dependent sectors by using specialized tools and processes to achieve strict manufacturing requirements. Let’s examine the various precision boring techniques that can help increase productivity, while also improving machining accuracy. Comprehending and employing these sophisticated methodologies can substantially impact the calibre of machined elements and overall efficiency.

The need for precision boring

Conventional boring procedures usually rely on human control and normal machining processes, and include enlarging pre-existing holes with basic instruments. Traditional processes, while still useful in some cases, are not always able to achieve high accuracy and tight tolerances. Exacting requirements are needed for components in modern production, necessitating procedures that are beyond the scope of traditional boring. The answer is precision boring, which is characterized by sophisticated instruments and methods that meticulously shape and refine surfaces. It is essential for maintaining tight tolerances and making sure that the components meet precise specifications. Precision is crucial for essential applications like aerospace and medical equipment as it directly affects functionality, safety, and performance. This underscores the critical role that precision boring plays, against traditional boring methods in today’s manufacturing environment.

Types of precision boring techniques

Single-point boring

Single-point boring is a precision machining process that involves using a single cutting tool to improve or expand an already-existing hole. This method is frequently used when extreme precision and accuracy are required. The cutting tool ensures a precise and regulated machining process by progressively removing material. Superior surface finishes and dimensional precision are achieved by careful control over the cutting operation made possible by the process’s simplicity.

Multi-point boring

Multi-point boring, as opposed to single-point boring, makes simultaneous use of several cutting edges. Comparing this approach to its single-point counterpart, there are significant advantages. By distributing the cutting forces more equally, the use of numerous cutting edges lowers tool wear and increases efficiency. Multi-point boring is a good option for applications that prioritize productivity and speed since it is frequently used in situations where higher material removal rates are necessary. Due to the simultaneous engagement of numerous cutting blades, this approach works particularly well for jobs involving bigger diameters and deeper depths. This results in a more efficient material removal procedure.

Fine boring

A specific kind of precision boring called fine boring is used to provide surface finishes with perfect tolerances. In situations where components require incredibly tight tolerances and refined surface characteristics, this technique is essential. The employment of specialized instruments made for accuracy—often with high-precision spindle systems and changeable boring heads—defines fine boring. Because fine boring can manufacture components with outstanding precision and surface quality, it is important because it can fulfil the demanding needs of sectors like aerospace and medical production. The machinery and tools used in fine boring applications are designed to be stable, precise, and able to deal with a variety of materials, guaranteeing the best results in even the most difficult machining jobs.

Advanced techniques for enhanced accuracy

Computer Numerical Control (CNC) Precision Boring

Because computerized control systems are integrated into the boring process, CNC precision boring has completely transformed the machining sector. Highly exact and repeatable processes are made possible by CNC machines, which are programmed to carry out precise tool motions. The ability of CNC to precisely regulate tool trajectories, spindle speeds, and feed rates sets it apart in the precision boring industry. This degree of automation guarantees that parts are continuously manufactured to exact specifications. The unpredictability that comes with hand machining is eliminated with CNC-controlled operations, producing increased precision and efficiency. This technique is especially useful for complicated tasks where precise tolerances and complex geometries are essential.

In-process measuring devices

Precision boring tools that have measuring devices integrated into them offer a proactive approach to machining. The CNC system is equipped with in-process measuring tools, such as sensors or probes, to keep an eye on the workpiece while it is being machined. These devices’ real-time feedback enables quick modifications to cutting settings in response to precise measurements. This helps to ensure precise machining by allowing for the identification of deviations from the intended dimensions and the implementation of corrective measures throughout the process. Measurement and feedback throughout the process not only guarantee precision, but also increase overall efficiency by lowering the requirement for post-machining modifications and inspections.

Advanced tool coatings

Modern coatings are essential for improving precision boring tool performance. The purpose of these coatings is to enhance wear resistance, increase hardness, and reduce friction. Cutting speeds are enhanced, tool life is extended, and tool wear is decreased when precision boring tools with coated surfaces are made using cutting-edge materials like titanium nitride (TiN) or diamond-like carbon (DLC). Additionally, by improving heat dissipation and chip evacuation, the coatings reduce the likelihood of tool failure. When these coatings are used on precision boring tools, the machining process becomes more economical, more efficient, and there is less downtime. Furthermore, the improved lubrication of coated tools makes cutting action smoother and maximizes the precision of the machining process.

Contributions to improved efficiency

Reduced downtime with high-speed boring

Reduced downtime in machining processes is one of the benefits of high-speed precision boring. High-speed boring’s faster cutting rates result in shorter cycle times, which speed up the completion of machining tasks. This production acceleration is especially helpful for companies that need to accomplish large volumes of manufacturing. Furthermore, because high-speed boring spends less time in contact with the workpiece, it reduces tool wear and increases tool life by lowering the need for frequent tool replacements. Because high-speed precision boring reduces downtime significantly, it is a desirable technology in current industrial environments owing to its efficiency.

Integration of coolant systems

For precision drilling to achieve maximum tool performance and machining efficiency, efficient coolant systems are essential. Coolant has several functions, including lubricating the cutting tool, removing chips from the cutting zone, and dispersing heat produced during cutting. In addition to shielding the workpiece from heat damage, proper cooling minimizes wear on the cutting tool and increases its lifespan. Additionally, by halting the workpiece material’s heat expansion, coolants aid in maintaining dimensional precision. The use of sophisticated coolant systems, such as high-pressure coolant supply, improves the overall efficiency of the precision boring operations and yields better tool life and consistent machining output.

Optimized tool paths and strategies

When it comes to precision boring, advanced toolpath optimization is essential to maximizing efficiency. Tool paths that have been optimized minimize pointless motions, which cut down on idle time and increase cycle efficiency. To accomplish the most efficient machining process, strategic toolpath planning takes into account variables including cutting pressures, material qualities, and machine capabilities. Reducing non-cutting durations and streamlining cutting routes result in faster cycle times and higher output. Furthermore, toolpath analysis and simulation made possible by contemporary software solutions enable additional machining strategy optimization for optimal efficiency in precision boring operations.

To sum up, precision boring techniques are essential to achieving the necessary accuracy in machining operations. The combination of sophisticated techniques improves accuracy and efficiency of operations. As a consequence, there is less downtime along with increased productivity. By adopting these state-of-the-art methods, manufacturers and machinists may better position themselves to fulfil the demanding requirements of contemporary precision machining. Within this framework, Bangalore-based Finetech Toolings stands out as a significant participant, offering cutting-edge precision boring tools. Industry experts can successfully traverse the ever-changing environment of precision production by staying informed and using the precision boring tools in Bangalore offered by Finetech Toolings.