While boring operations are essential to machining operations, they are not without difficulties that might compromise accuracy and efficiency. The blog below covers all of the typical challenges that are encountered during boring operations, from surface quality concerns to chatter and tool deflection. With this blog, we seek to enable machinists to overcome these obstacles and provide the best outcomes by offering doable alternatives.

Understanding the basics of boring operations

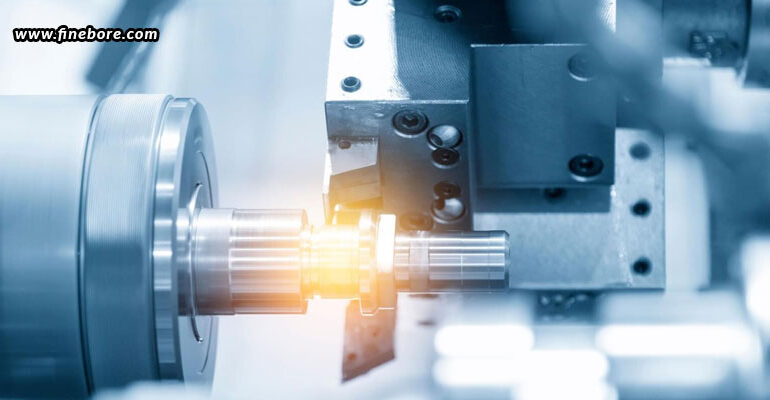

Boring operations are the cornerstone of machining operations in the pursuit of accurate interior diameters in a variety of industries. Boring is essentially a machining process used to ensure precise dimensional accuracy by enlarging and refining preexisting holes. This invaluable procedure is used in the manufacturing of parts that need complex internal characteristics, such as gearboxes, hydraulic cylinders, and engine cylinders. The accuracy attained by boring operations is crucial in several industries, including industrial machinery, hydraulic systems, and the automobile industry. This meticulous process of honing interior dimensions highlights the vital role boring plays in forming the framework of different mechanical systems and guaranteeing dependability and performance in the gear that runs our society.

Common challenges in boring and their solutions

Common problems in boring operations include chatter, tool deflection, and surface finish quality issues. Optimizing cutting conditions, choosing the right tools, and modifying feeds and speeds are only a few ways to guarantee accuracy and productivity during the machining procedure. Let’s get into the details below.

Chatter

Unfavourable tool geometry or incorrect cutting conditions can often lead to chatter during boring operations. For efficient chatter reduction measures, it is important to first comprehend the causes. Inadequate feeds, rates, or depths of cut can lead to improper cutting conditions, which can cause vibrations at the tool-workpiece interface. Furthermore, the issue may be made worse by inadequate tool geometry, such as tool rake angles and innovative setups.

Solutions: Machinists can use a variety of efficient reduction strategies to avoid chatter. A vital part is optimizing cutting parameters, such as adjusting feeds and speeds in accordance with material and tool requirements. Vibrations can be reduced by using appropriate tool materials, such as carbide inserts designed for stability and precision. Damping techniques, including sophisticated cutting fluids or anti-vibration toolholders, are equally important for absorbing and dissipating vibrations. In addition to reducing chatter, good tool setup, stiffness, and fixturing also help to provide a stable machining environment. Thus, reducing chatter in boring operations requires a multifaceted strategy. Machinists may reduce chatter and achieve smoother, more accurate machining operations by adjusting cutting conditions, using the right tool materials, and putting damping measures into place.

Tool deflection

Tool deflection occurs during boring operations when the cutting tool flexes or bends as a result of the applied cutting forces, affecting the machined workpiece’s dimensional precision. Numerous elements, such as the geometry, cutting forces, and material characteristics of the tool, contribute to this deflection. Tool deflection may cause variations in the dimensions that are machined, which might compromise the accuracy and calibre of the finished product. Errors in the machined features might occur and jeopardize the component’s overall performance and operation.

Solutions: In order to reduce tool deflection and preserve dimensional accuracy, machinists have several options. Reducing the feed rate minimizes the tool’s bending and helps in controlling the cutting forces, making it a crucial strategy. Choosing the right tool geometries, such as shorter lengths or smaller diameters, also lessens the likelihood of deflection. Another important part of minimizing tool deflection is the use of stiff tool configurations. Overall stiffness is improved by using strong toolholders and making sure there is a strong connection between the tool and the machine spindle. When choosing a tool material, machinists should take into account its strength and stiffness, choosing materials that offer the best support and are resistant to bending. By using these steps, machinists may successfully reduce tool deflection, maintaining dimensional precision and achieving better boring results.

Surface finish problems

A number of things can lead to poor surface finish in boring operations, but two major reasons are insufficient coolant flow and improper tool selection. Inappropriate tool selection can result in uneven cutting and imperfections on the machined surface. Examples of this include employing a tool with the wrong geometry or a worn-out cutting edge. Poor surface quality and thermal degradation are the results of insufficient heat dissipation caused by inadequate coolant flow, which makes the problem worse.

Solutions: Enhancing surface finish necessitates a diverse strategy. To achieve a smooth surface, feeds and speeds must be optimized. To guarantee adequate chip drainage and avoid excessive tool wear, machinists must carefully modify the cutting parameters. Achieving a finer surface finish is made easier by the selection of suitable tool coatings, such as those that increase wear resistance or decrease friction. Enhancing surface quality also heavily depends on smart coolant techniques. An improved surface finish can be achieved by preventing tool overheating, reducing friction, and dissipating heat through proper coolant flow and application. It is the responsibility of machinists to guarantee that coolant systems are properly maintained and adjusted for the particular machining task at hand. Through the use of these procedures, machinists may tackle the underlying reasons for subpar surface quality in boring operations, leading to increased accuracy, enhanced appearance, and increased overall component quality.

Best practices

Following best practices is essential to optimizing boring processes and getting better outcomes. To guarantee optimum performance, start with careful tool selection, taking into account elements like geometry, material, and coatings. Maintaining correct tool alignment, fixturing, and toolholder stability is essential for minimizing vibrations and deflections; meticulous machine setup also being crucial. Adjusting cutting parameters for the particular material and application, such as feeds, speeds, and cut depths is also necessary. Throughout the machining process, constant observation and modification are essential. Machinists should keep a close eye on surface quality, tool wear, and dimensional accuracy, and adapt in real time as required. Checking the flow of coolant often makes sure it efficiently dissipates heat and facilitates chip evacuation. In addition to ensuring the immediate success of the boring operation, this proactive approach to monitoring and modification also helps to maintain long-term machinery and tool health, promoting an efficient and precise culture.

To sum up, resolving typical problems in boring operations is essential to attaining superior machining results. The methods offered should be used by machinists to promote a proactive mindset and improve accuracy and efficiency. Long-term success is influenced by constant observation, modification, and adherence to best practices. FineTech Toolings is one of the most renowned boring tools suppliers in Bangalore that offers high-quality boring tools, proving to be a dependable partner for machinists aiming for accuracy and success in every boring operation, thanks to their dedication to high-quality and cutting-edge tooling solutions. Increase the precision of your machining with FineTech Toolings as your reliable source.