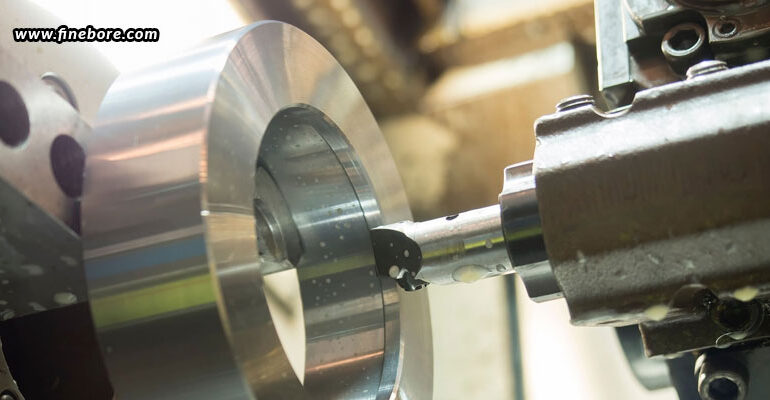

The art of boring is an essential skill in the field of machining that requires dexterity, knowledge, and a thorough comprehension of the nuances involved. Learning the proper boring techniques is essential to producing excellent surface finishes and streamlining the machining process as machinists work to become experts in their field. Let us now look at some pointers that set such expert machinists apart from average ones.

Expert machinists carefully choose their tools

Choosing the proper instruments is the first step towards learning boring skills. Performance can be greatly affected by the boring bar type, the insert shape, and the coating. When selecting tools for a particular project, expert machinists take into account things like the required surface finish, cutting forces, and material compatibility. And, this is the reason why they rely on expert boring tools suppliers in Bangalore, one like FineTech Toolings, who can provide them with the best tools to maximize their efforts.

Expert machinists maintain rigidity to bring about precise results

It’s critical to maintain rigidity in the setup, as the accuracy of boring operations can be affected by vibrations and deflections. Securing workpieces and tooling is what expert machinists concentrate on to reduce unwanted movement, particularly when working with challenging materials or long overhangs.

Expert machinists identify and maintain optimal feeds and speeds

Within the art of machining, there is an art to fine-tuning speeds and feeds. Finding the ideal mix guarantees effective removal of material without wearing down the tools or sacrificing the surface finish. To achieve this delicate equilibrium, expert machinists take into account factors like machine capability, tooling, and workpiece material.

Expert machinists adopt cutting-edge toolpath techniques

Expert machinists use sophisticated toolpath methods made possible by modern machining technologies to achieve the best possible outcomes. Trochoidal milling, adaptive toolpaths, and high-speed machining are a few examples of methods that improve productivity in boring operations without sacrificing accuracy.

Expert machinists pay attention to the choice of cutting fluids

Cutting fluids are used in boring operations to serve a number of purposes such as dissipating heat, reducing friction, and evacuating chips. Achieving the optimum surface finish and prolonging tool life require careful selection of the appropriate cutting fluid, while also ensuring a consistent application, which is what expert machinists play close attention to.

Expert machinists look out for and address tool wear

Keeping an eye on and managing tool wear is a necessary skill, as persistent performance during the boring process can be maintained by routine inspections, changing tools, and recognizing wear indicators. Expert machinists are thus always on the look out for any such possible issues.

Expert machinists utilize technology for measurements

Boring operations get an additional layer of quality control when measurement technologies, such as post-process inspection and in-process gauging, are used. Expert machinists use such technologies to verify that the finished product satisfies the necessary requirements, while also making any necessary alterations in real time if not satisfied.

A strong commitment to accuracy, a thorough understanding of tools and materials, and a readiness to adopt new technologies are all necessary for mastering boring procedures. Expert machinists implement all the above strategies and tips to streamline their boring operations, while bringing about the best possible outcomes, which is what sets them apart from other average-rated machinists.