Micro-boring heads are now essential tools in the field of precision machining, where accuracy is critical. These specialized cutting tools are intended to create holes with tight tolerances, frequently within microns, that are incredibly precise and small in diameter. They are especially important in sectors like electronics, aircraft, and medical device manufacture where even the smallest deviation can have serious repercussions. The significance of micro-boring heads, their uses in high-precision manufacturing, and how they help sectors satisfy demanding quality standards will all be covered in this blog.

Importance of micro-boring heads in high-precision manufacturing

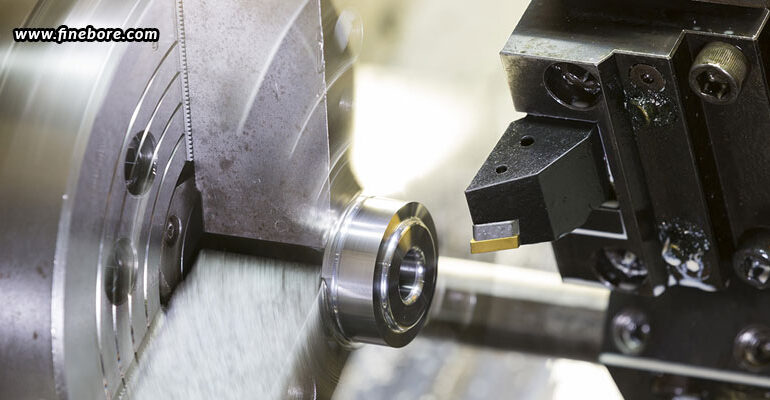

A smaller, more precise version of conventional boring heads, micro-boring heads are designed to create smaller holes. They are made to provide surface finishes, concentricity, and dimension accuracy that are impossible to get with conventional tools. These heads are useful for applications needing the highest levels of accuracy because they are typically used for hole diameters ranging from less than 1 mm to a few millimetres. These tools are not merely tiny replicas of standard boring heads; they are designed to take into account the particular difficulties presented by micro-machining. When working with smaller dimensions, problems like vibration, tool deflection, and material characteristics become much more critical. Micro-boring heads are made to help reduce these difficulties.

Tight tolerances and small dimensions

The specialized design of micro-boring heads allows for incredibly tight tolerances, frequently as little as a few microns. This is especially crucial in sectors like the manufacturing of medical devices, where parts must fit together precisely, if not perfectly. To guarantee correct operation and patient safety, for example, precise standards are needed for surgical instruments, implants, and diagnostic equipment.

Superior surface finishes

The ability of micro-boring heads to provide clean surface finishes is another important feature. Surface quality can have an immediate effect on performance in applications such as the manufacturing of medical devices. Rough surfaces on implants, for example, may result in greater wear or friction and long-term dependability problems. Smooth surface finishes are guaranteed by micro-boring heads, which raises the overall calibre of the finished product.

Minimal tool deflection

Even a small amount of tool deflection while working with incredibly small diameters can lead to incorrect holes. Rigidity is a key consideration in the construction of micro-boring heads, which reduces deflection and guarantees uniform hole sizes. This is important when machining materials that are difficult to machine because of their strength and hardness, such as titanium and stainless steel, which are widely used in the aerospace and medical industries.

How micro-boring heads overcome machining challenges

Material properties

Because of their hardness and toughness, materials like titanium, stainless steel, and other composites that are frequently employed in high-precision industries can be challenging to process. In order to increase tool life and improve performance when machining these difficult materials, micro-boring heads are usually constructed from high-performance materials like carbide or coated with wear-resistant compounds.

Vibration and tool deflection

When micro-machining, two major obstacles are vibration and deflection. To reduce these problems, micro-boring heads are made with highly robust construction and sophisticated dampening systems. To further improve precision, some designs additionally include specialized coatings that reduce friction and wear.

Tool wear

At the micro scale, surface smoothness and precision of the finished product can be significantly affected by minimal tool wear. In order to counteract this, manufacturers of micro-boring heads frequently employ cutting-edge coatings like titanium nitride (TiN) or diamond-like carbon (DLC), which strengthen the tool and reduce wear over time.

Applications of micro-boring heads in precision industries

Medical device manufacturing

One of the biggest markets for micro-boring technology is the medical device industry. High-precision machining is necessary for devices like stents, catheters, pacemakers, and prosthetics because they are inserted in or used on human bodies, which have very tight tolerances.

- Surgical instruments: A variety of surgical instruments, including forceps, scalpels, and bone drills, require complex designs with precisely sized holes. The incredibly precise construction of these complex features is made possible by micro-boring heads.

- Prosthetics and implants: To ensure that dental or medical implants fit inside the body and perform as intended, they must be incredibly precise. Micro-boring heads create precise fits and smooth surfaces, ensuring that the implants live up to these high requirements.

- Diagnostic equipment: Devices like endoscopes and imaging tools require parts that are precisely made and have intricate, small characteristics. In order to ensure the dependability and efficiency of these parts during medical procedures, micro-boring heads are crucial in their production.

Aerospace industry

The aerospace industry requires the highest levels of precision in all of its components since even minor errors can have disastrous results. Components like fuel injectors, sensors, and other tiny, high-performance elements are made with micro-boring heads.

- Fuel injectors: To guarantee proper fuel flow and combustion efficiency, fuel injectors need extremely accurate holes. Reduced engine performance or engine failure can result from even the smallest error in the diameter or positioning of these holes. Manufacturers are able to achieve the precise tolerances needed for these vital components, thanks to micro-boring heads.

- Sensors and instrumentation: To keep an eye on engine performance, climatic conditions, and flight systems, the aerospace industry uses a wide range of sensors. These sensors frequently have tiny parts that need to be machined precisely in order to guarantee accuracy and dependability, which is where micro-boring heads come into play.

Electronics industry

Miniaturization is becoming more and more necessary in the quickly developing electronics industry. Micro-boring heads are employed in the manufacturing of a number of components, including circuit boards, connections, and microchips.

- Printed Circuit Boards (PCBs): In order to facilitate electrical connections, PCBs frequently need small, precise holes. These precise-sized holes can be made in electronic equipment using micro-boring heads, which guarantees maximum conductivity and dependability.

- Microchips and semiconductors: Because the components on microchips are frequently on the order of microns, the semiconductor sector demands extremely precise manufacturing. In order to machine these parts and provide the accuracy required for high-performance electrical devices, micro-boring heads play a very important role.

In order to achieve the strict quality demands of industries like electronics, aerospace, and medical equipment, micro-boring heads are crucial tools in high-precision manufacturing. Micro-boring heads are essential for modern production because they enable manufacturers to achieve incredibly tight tolerances, excellent surface finishes, and reliable precision. The significance of these specialized tools will only increase as industries continue to push the limits of what can be achieved with micro-manufacturing. Leading precision boring head supplier in Bangalore, Finetech Toolings, is at the forefront of providing cutting-edge solutions for ultra-precise machining. Not only is Finetech Toolings one of the leading precision boring head manufacturers in Bangalore offering high quality micro-boring heads, but in fact also an entire micro-boring kit designed for ultra-tight tolerances in high-precision manufacturing. The advanced tooling solutions ensure superior performance in industries like aerospace and medical devices. This micro-boring head technology is set to reach new heights in the future, thanks to advancements in automation, material science, and smart tooling.