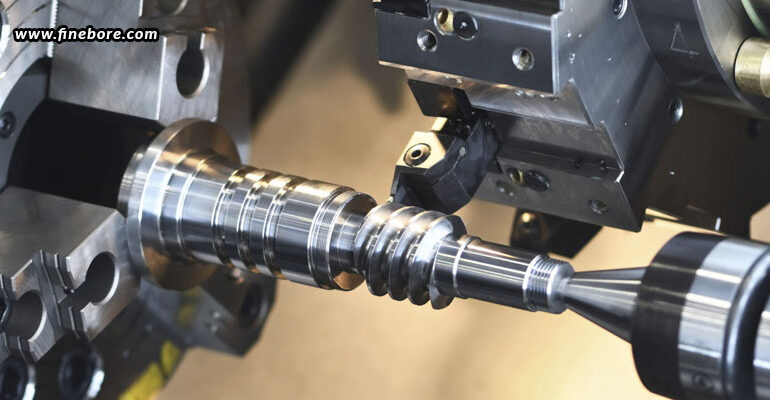

Because of their ability to produce deep holes, cylindrical cuts, and precise tolerances with accuracy, boring tools are essential in precision machining. Like any tool, though, their performance can be significantly improved by applying advanced techniques and optimization approaches. This blog will cover professional advice on how to get the most out of your boring tools in terms of longevity, accuracy, and efficiency. You can get better outcomes in your machining operations by using these tactics, which range from optimizing settings to implementing performance-enhancing adjustments.

Choosing the right tool material for enhanced durability

For boring tools, selecting the proper material is essential to optimizing longevity and performance. Certain materials, such as carbide, cubic boron nitride (CBN), and high-speed steel (HSS), are best suited for certain applications. Because of their well-known hardness and heat resistance, carbide inserts are ideal for high-speed operations and materials such as superalloys, cast iron, and stainless steel. Conversely, CBN inserts substantially extend tool life, minimize wear, and are ideal for cutting harder steels. Furthermore, by reducing friction and increasing cutting efficiency, coated inserts like titanium nitride (TiN) or aluminium oxide (AlO₃) can further enhance tool durability.

Optimizing tool geometry for better efficiency

Your boring tool’s cutting forces, surface finish, and tool life can all be significantly increased by optimizing its geometry. Significant improvements can result from even small changes to the rake and clearance angles. For example, increasing the positive rake angle improves surface smoothness and lowers cutting forces; however, it may also weaken the tool. In a similar vein, minimizing excessive friction requires optimizing the clearance angle; larger angles enable smoother cuts, while lower angles increase tool stiffness. Although it may result in chatter during light finishing operations, adjusting the nose radius can also have an impact since a greater radius enhances surface finish and more evenly distributes cutting forces.

Making use of dampening devices and advanced toolholders

Chatter and tool deflection are frequent consequences of vibration, a common problem in boring operations. Vibration-dampening technology integrated into toolholders may significantly enhance performance. Superior clamping force and accurate alignment are provided by hydraulic toolholders, which lower vibration and increase tool life. Long-reach applications also benefit greatly from vibration-dampened boring bars with internal damping devices. This is especially crucial for deep-hole boring since tool deflection can be a big issue.

Optimizing speed and feed rates

Optimizing the speed, feed, and depth of cut is one of the easiest yet most efficient methods to enhance boring tool performance. It’s important to make sure that the spindle speed corresponds with the material and tool geometry because, for instance, carbide tools can withstand greater speeds without experiencing undue wear. Lowering the feed rate for finishing passes improves precision and surface finishes. Balancing the depth of cut is essential for deep boring operations in order to minimize deflection and heat accumulation, and guarantee optimal tool performance.

Using coolant systems to manage heat

One important aspect influencing the lifespan and efficacy of cutting tools is heat. Overheating can lead to thermal deformation, reduced tool life, and degraded bore quality. By supplying coolant straight to the cutting edge, through-tool coolant systems are very successful in decreasing chip accumulation and increasing tool longevity. Flood coolant facilitates more effective chip evacuation and guarantees uniform heat distribution during extended boring operations. However, a coolant may not always be required in hard turning or dry cutting processes when dry machining is combined with advanced inserts like ceramics or CBN.

Chip control methods to increase accuracy

Preventing tool damage and preserving accuracy depend on efficient chip control. The performance of boring tools can be significantly enhanced by using the right chip evacuation strategies. Chip creation is controlled by inserts with integrated chip breakers, which facilitates chip removal from the bore. Air blasts or vacuum systems are great substitutes for coolant in applications when it is not possible to remove chips from the cutting zone, avoid recutting, and reduce tool damage.

Inspection and routine tool maintenance

For boring tools to last a long time and operate at their best, regular maintenance and care is crucial. Avoiding machining problems can be achieved by establishing a routine for component replacement, sharpening, and inspection. Wear indicators like chipping or dull edges should be checked for on a regular basis, and worn tools should be replaced or re-sharpened before they degrade the quality of the work. While carbide tools benefit from accurate sharpening using diamond grinding wheels, high-speed steel (HSS) and polycrystalline diamond (PCD) tools need to be sharpened frequently to maintain cutting efficiency. Furthermore, timely replacement of worn inserts guarantees ideal cutting conditions and avoids needless tool damage.

Consulting with tooling experts for custom solutions

It might be very helpful to consult tooling professionals when handling extremely difficult boring tasks. For particular machining requirements, including odd-shaped bores, special material characteristics, or strict tolerances, tooling experts may offer specialized solutions. To make sure you get the appropriate tool for your unique needs, many manufacturers provide tooling trials that let you test various boring tools or modifications under actual operating settings. For the best boring tools and expert guidance, FineTech Toolings provides a variety of precision boring solutions tailored to your specific machining needs. With the expertise and high-quality products from these boring tools suppliers in Bangalore, you can boost the performance of your boring tools to new heights.

Advanced machining processes, proper setup, and cautious tool selection are all necessary to improve boring tool performance. You can improve the effectiveness, accuracy, and lifespan of your boring tools by putting the professional advice in this blog to use. This advice covers everything from material optimization and vibration management, to correct maintenance and routine inspections. These techniques can help you get the most out of your boring operations, whether you’re cutting complex geometries, aiming to achieve fine tolerances, or are performing deep hole boring.