Sustainability In Machining – Eco-Friendly Boring Bar Designs & Practices

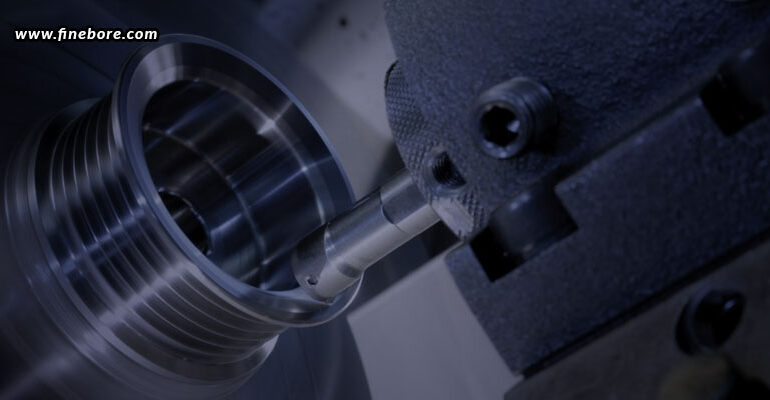

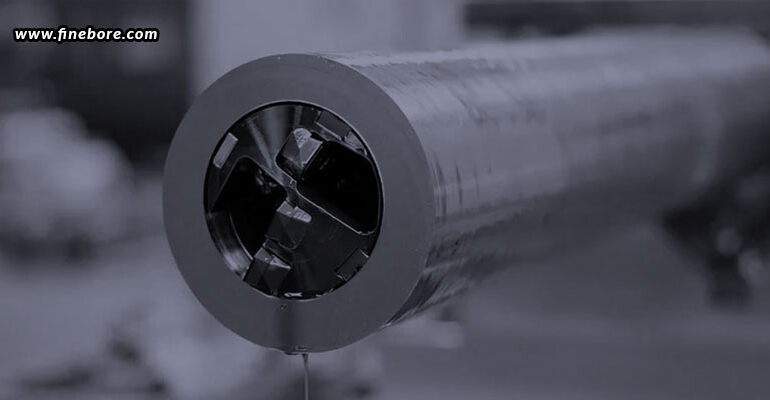

Sustainability has transitioned from being a mere trend in contemporary manufacturing to an essential strategy. As industries aim to lower carbon emissions, save energy, and embrace circular economy concepts, machining methods are experiencing a significant transformation. Among the various tooling systems utilized in metalworking, boring bars are