Hole-making makes the largest share of all machining operations, including drilling, grinding, milling, and more. The first basic step to create a hole is generally drilling, but this may require additional procedures to meet straightness, surface finish, and diameter tolerance requirements. One such procedure that is widely used is “boring”.

What is boring?

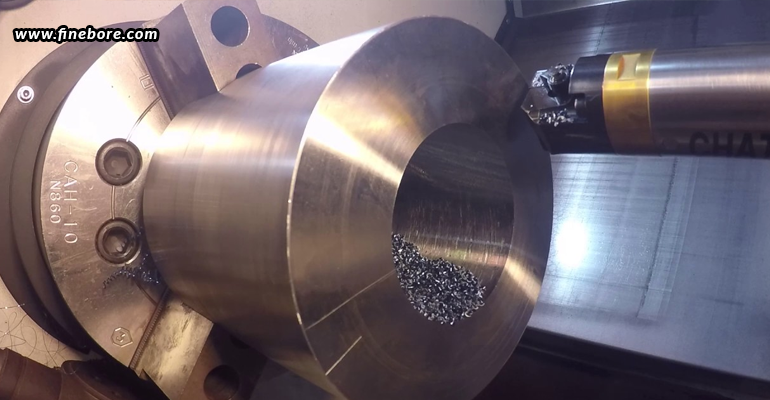

Boring uses a single-point cutting tool, called the boring bar, to remove material so as to create the perfect hole diameter required by the application. A dual-headed boring arrangement may also be required in some applications, which supports higher metal removal rates, and roughing and finishing in a single pass. Machine operators generally use two types of boring – one done on a lathe, and the other on a machining center. The tooling, machining parameters, and metal removal approach, all vary significantly, based on the desired hole depth, hole diameter, tolerance, workpiece material, and many other such factors, which can make boring either relatively easy, or exceedingly difficult. And, to make it convenient and precise, you want the right boring tools. Finetech Toolings is one of the most reliable boring tools suppliers in Bangalore, where you can get all sorts of boring tools, boring bars, boring heads, and related accessories, all being industry-specific in nature, and in conformance to international quality standards.

The challenge faced while boring

One of the many difficulties that are experienced during the boring application is “chatter” – a noisy harmonic generated event or vibration that leads to poor tool life and unacceptable surface finish. This chatter may be caused by an overly long boring bar being used. Fortunately, there are a few ways in which this can be managed and reduced.

How to manage chatter?

Whether it is chatter, or problems with tool life and hole accuracy, boring can seem to be a challenging task. Nevertheless, if the right guidelines are followed, boring shouldn’t be more difficult than any other type of machining process. Let’s help you know some techniques that can be used to mitigate chatter, no matter how deep the hole may be, along with enhancing tool life, and hole accuracy.

- Try reducing the cutting speed, and increasing the feed rate. Alternatively, you can try increasing the cutting speed, and decreasing the feed rate. Whatever you do, adjust one variable at a time, and that too by only a small amount, say for example, only 10% either way. Check on the results after you make the alterations. If the results aren’t as desired, put the value back, and try a different combination. Continue with this method, until you obtain the desired results.

- Generally, the Depth of Cut should be equal to or greater than the Tool Nose Radius. If too heavy, try using a smaller nose radius. Take lighter cuts at slightly higher feed rates. Keep altering until you find the right balance of cutting forces, chip control, and vibration dampening.

- Using the largest boring bar for the hole can create the least deflection. However, there must be room for effective chip evacuation, which is not provided, can lead to disastrous results. You should also know how much of the bar you should be hanging on to, which is generally four times the bar diameter.

- Finally, the boring bar alignment is absolutely critical. The tooltip should sit perfectly on the hole center line. Most bars have a flat ground on the top, which simplifies the process. Also, you must avoid clamping the bar with set screws; a sleeve or collet that wraps completely around the shank will provide a more secure grip.

Using one or more of the above tactics, it is possible to have an accurate and productive boring process. So, keep trying until you get it right, but ensure that you aren’t compromising on your tool life or surface finish. In addition, the hole diameter should also be perfect to the dimension required.