Boring tools are typically thought of as being used in woodworking and construction, but they have shown to be very adaptive in deep-sea and outer-space research environments. These cutting-edge technologically advanced instruments withstand the intense heat and crushing pressure of space and the deepest depths. Let’s explore the technical feats that went into creating these tools, emphasizing the ideas and technologies that make them resistant to the extreme conditions found in space and the deep sea. Prepare to be amazed as we explore the depths and go beyond our environment to discover the astounding potential of these seemingly commonplace tools.

Deep-sea exploration

Deep-sea exploration poses extreme difficulties, requiring innovative modifications for boring tools to withstand the corrosive and crushing conditions of the abyss. These challenges have been creatively addressed by engineers, who have created ways to overcome them and enable tools to go through the extremely deep ocean floor. In an environment full of corrosive substances, the longevity of these tools is guaranteed by corrosion-resistant materials. Scientists and researchers may explore and study the secrets buried in the deep-sea environment while protecting humans from harsh underwater circumstances thanks to remotely operated vehicles (ROVs) outfitted with these cutting-edge tools. With the use of robust boring equipment, this cutting-edge method of deep-sea research has increased our understanding of the ocean floor and its distinctive ecosystems, highlighting the vital role that engineering plays in discovering the mysteries of the abyss.

Extreme pressures

Examining the technology underlying extremely powerful boring tools reveals a world of possibilities. With the use of cutting-edge materials and designs, engineers have created pressure-resistant seals and casings to protect equipment from the harsh conditions found in deep-sea habitats. The tools are protected from the intense pressure present in the ocean’s depths by these casings, which serve as a barrier. The creation of certain materials that are immune to rust and degradation guarantees the longevity of these instruments even after extended exposure to abrasive underwater environments. Modern design methods are also used by engineers to improve the tools’ structural integrity and make them more resistant to the intense pressures at work. The inclusion of pressure-resistant characteristics is essential to the dependability and efficiency of these boring tools, demonstrating the creativity and commitment of engineers to push the boundaries of technology in the quest for deeper understanding and exploration of the ocean’s mysteries.

Extreme temperatures

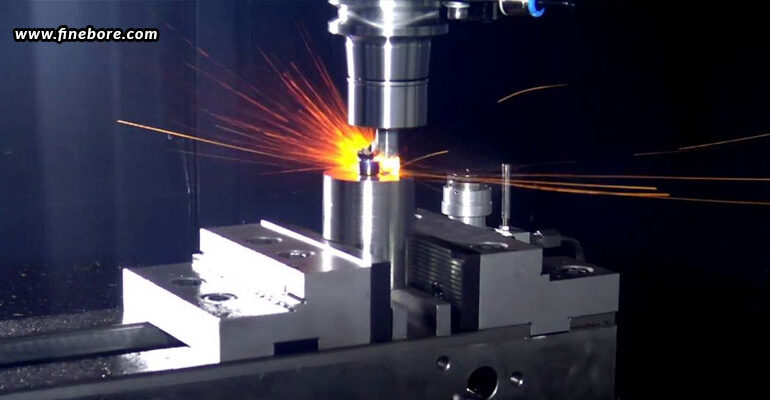

For boring tools to work well under the spacecraft’s severe temperature conditions, extraordinary engineering is required. Temperatures in space can vary greatly, ranging from intense heat to bitter cold. Scientists use advanced thermal control systems and insulation methods to protect these instruments from the high-temperature changes seen on space exploration flights. Cutting-edge thermal management technologies enable boring equipment used for space missions to maintain a constant temperature and avoid freezing or overheating. In order to survive the extreme heat produced during boring, these systems frequently make use of heat-resistant materials and coatings, as well as insulating layers to keep warmth in during cold temperatures. Furthermore, numerous tools may utilize active cooling techniques, including built-in fans or coolant circulation systems, to better dynamically control temperature variations. In the hostile environment of space, boring tools are guaranteed to last and perform properly thanks to this meticulous consideration of thermal characteristics.

Innovative materials

The endurance of boring instruments under harsh circumstances is shown by unlocking the mysteries of state-of-the-art materials. In order to protect equipment from the corrosive elements present at ocean depths, engineers use sophisticated alloys with corrosion-resistant qualities for deep-sea applications. These alloys not only endure the constant pressures, but also guarantee lifetime, conquering obstacles that would quickly deteriorate traditional equipment. Space-grade materials are revolutionizing tool manufacture in space. Because of their remarkable strength-to-weight ratios, these composites offer longevity without increasing the tool’s total weight. Space-grade materials are made to survive extremes in temperature as well as the vacuum of space, having been designed to tolerate severe circumstances outside our atmosphere. These cutting-edge materials help boring tools last longer and be more reliable as engineers continue to push the boundaries of innovation. They are essential for deep-sea exploration and space missions, where conventional equipment would break down in the harsh conditions.

In conclusion, boring tools are essential for both deep-sea and space research because of their capacity to adapt to harsh environments. The astounding technical achievements show how human creativity and technology prowess may overcome obstacles. These boring tools will surely remain essential for solving the mysteries of the deep sea and expanding our knowledge of the universe as exploration boundaries grow. FineTech Toolings is a leading innovator in precision boring tools in Bangalore, with a dedication to providing cutting-edge tooling solutions that contribute to the success of numerous sectors. Embrace the precision and reliability of FineTech Toolings for all your boring needs, ensuring optimal performance in every challenging environment.