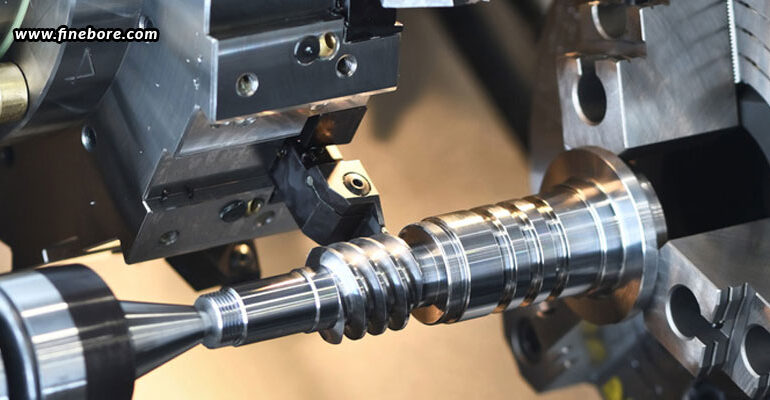

Effective tool maintenance is crucial for maximizing durability, performance, and efficiency in machining tasks. Whether utilizing precision boring tools, drills, or milling cutters, proper maintenance minimizes downtime, enhances accuracy, and reduces replacement expenses. Neglecting tool care can lead to diminished efficiency, increased wear, and costly machine breakdowns. Regular maintenance not only extends tool lifespan but also improves machining precision, decreases material waste, and promotes safety during operations. By implementing key maintenance practices, beginners can ensure their tools remain in optimal condition, delivering consistent performance and reliability in every machining process.

Cleaning and lubrication

It is essential to clean all the tools post usage. After each machining operation, it is important to clear away debris, chips, and coolant residues from tools. However, it is imperative to only utilize compressed air, soft brushes, or appropriate cleaning solutions that are compatible with the tool material. Moreover, adequate lubrication minimizes friction and heat generation, thereby preventing early wear. Applying the appropriate lubricants to cutting edges and moving components is important, while adhering to the manufacturer’s guidelines.

Appropriate storage for prolonged tool longevity

Designated racks, cabinets, or cases should be utilized for tool storage to prevent potential damage. Protective covers must be employed for precision boring tools and inserts to avoid chipping. Tools should be kept in a dry, temperature-regulated environment to prevent corrosion.

Routine inspection and condition assessment

Regular inspections should be conducted to detect early signs of wear, chipping, or damage. Magnifying tools, micrometres, and bore gauges must be used to verify dimensions and confirm adherence to necessary tolerances. Worn tools should be replaced before machining quality is compromised.

Tool sharpening and reconditioning

Cutting edges should be sharpened regularly to sustain optimal performance. Tools such as drills, reamers, and end mills must be reconditioned or reground to extend their lifespan. Professional reconditioning services can be engaged to restore precision to costly tools, reducing expenses over time.

Maintaining quality of coolant and cutting fluids

Cutting fluids should be monitored and replaced regularly to prevent contamination that may damage tools and workpieces. Appropriate cutting fluids must be selected based on the material being machined, and effective filtration and recycling practices should be implemented for sustainability.

Avoiding common tool maintenance errors

Neglecting tool wear should be avoided, as using dull or damaged tools may compromise machining accuracy and place undue stress on the machine. Proper lubrication must be ensured to reduce heat and friction, preventing premature tool failure. Additionally, tools should not be stacked or left unprotected to avoid physical damage and rust.

Collaborating with reliable tool suppliers

To ensure optimal machining performance, tools must be procured from reputable suppliers. FineTech Toolings, a leading supplier of precision boring tools in Bangalore, offers tools designed for durability and efficiency. Access to high-quality tools requiring minimal maintenance can be ensured by collaborating with trustworthy manufacturers, guaranteeing consistent performance in machining operations.

In summary, effective tool maintenance maximizes durability, performance, and efficiency in machining. Regular cleaning, lubrication, proper storage, and routine inspections prevent wear, reduce downtime, and ensure precision. Sharpening tools, maintaining coolant quality, and avoiding common maintenance mistakes further extend tool life. Implementing these best practices helps optimize machining performance, minimize replacement costs, and maintain consistency in operations.