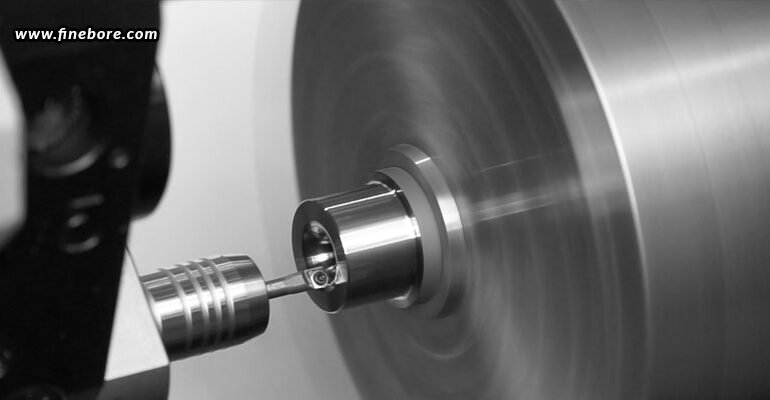

Tight spaces are frequently a major issue in the realm of precision machining. In such cramped spaces, standard tools may not function well, which can result in problems like poor surface finishes, vibration, and insufficient reach. Compact boring bars are useful in this situation. These tools, which are designed especially for confined spaces, provide creative solutions that guarantee accuracy and effectiveness without sacrificing functionality. The difficulties of machining in confined places, the special qualities of compact boring bars, and how they improve usability in limited settings will all be covered in the blog below.

Why tight spaces require specialized tools

Tight machining spaces, like deep cavities or small-diameter holes, provide difficulties like limited tool clearance, which can cause interference with the workpiece or machine parts, resulting in damage and inefficiency. Because long or large tools are less stiff in such cramped areas, there is a greater chance of vibration or chatter, which could compromise the surface finish and precision. Because minor misalignments can cause large inaccuracies, excellent precision in these settings demands equipment made especially for stability and control. Furthermore, certain applications, such as creating complex components for medical or aeronautical systems, call for tools that can access difficult-to-reach places without compromising accuracy. Compact boring bars are designed to get around these obstacles with skill and provide the best possible performance.

Key features of compact boring bars

Compact boring bars are nimble, space-efficient tools made for accurate machining in tight spaces. Even under difficult circumstances, their minimized overhang guarantees optimal rigidity, reducing deflection and vibration for precise outcomes. They are perfect for delicate machining tasks because of their lightweight, slender forms, which make it easy to access tiny cavities and small-diameter holes. Compact boring bars, which are made of premium materials like carbide, are incredibly durable and frequently have vibration-dampening technologies for increased stability. Effective chip removal and heat dissipation are guaranteed by internal coolant tubes, especially in deep-hole applications. Modular setups also enable interchangeable cutting heads and adjustable lengths, which add adaptability that is crucial for industries with a range of machining requirements.

Advantages of compact boring bars

Compact boring bars have several benefits. By offering better control and stability, they provide increased precision and guarantee greater accuracy even in difficult machining situations. They provide better surface finishes by lowering deflection and vibration, which lessens the need for extra finishing procedures. They simplify the machining process and boost production by removing the need for complicated setups or additional equipment due to their ability to enter restricted spaces. These tools are an affordable option for precision machining since they also lessen tool wear and machining errors, which lowers operating costs and prolongs tool life.

Using compact boring bars effectively

Even though compact boring bars have many advantages, using them properly is crucial to getting the most out of them. Choosing a tool that is appropriate for the workpiece’s size and material—such as coated tools for abrasive materials or carbide bars for hard metals—is crucial to getting the best results with compact boring bars. Optimizing cutting parameters by modifying feed rates, speeds, and depth of cut in accordance with material and tool specifications is also essential. Minimizing tool overhang improves stiffness and decreases deflection. To prevent errors, the boring bar must be properly aligned with the machine axis. Additionally, routine maintenance, such as checking for wear, chips, or cracks, guarantees accuracy and prolongs tool life.

Where are compact boring bars mostly used?

Compact boring bars are widely used in a variety of industries where accuracy in confined spaces is essential. They are crucial to the production of complex components like engine parts and turbine blades in the aerospace industry. They are essential to the medical device industry because they can precisely machine small, intricate items like implants and surgical equipment. When making tiny holes in engine parts, they guarantee precision and uniformity in the automobile industry. Compact boring bars are also essential in the production of moulds and dies, as their capacity to work in confined areas and provide smooth finishes is essential for effectively creating complex moulds and dies.

As we can see, compact boring bars provide remarkable precision, stability, and versatility, making them essential equipment for machining in confined spaces. For industries where precise machining is essential, such as aerospace, automotive, and medical manufacture, their svelte forms, premium materials, and cutting-edge features prove to be essential. Even in the most constrained settings, machinists can achieve effective, high-quality results by employing them skillfully. FineTech Toolings stands out as a reliable supplier for individuals looking for excellent compact boring bars in Bangalore, offering tools made to the highest levels of accuracy and dependability.