In order to enlarge holes to precise dimensions, machining activities require the use of boring tools, which are crucial for precision and accuracy. For long-lasting and reliable use, it’s essential to provide boring bars, boring heads, and all other boring tools with the right upkeep and care. You can significantly boost productivity, decrease downtime, and prolong the life of your boring tools by adhering to recommended methods for maintenance, storage, sharpening, and component replacement. We’ll go over specific upkeep and care guidelines in this blog that all operators and machinists should adhere to in order to maintain the best possible state for their boring tools.

Cleaning boring tools to prevent wear and tear

Boring tools require routine cleaning in order to remain effective and long-lasting. Premature wear can result from metal fragments, chips, and coolant residues building up on the tool’s surface. One of the best practices is to use a clean cloth to wipe off the tool after each usage in order to eliminate coolant and metal shards. Chips from difficult-to-reach places can be removed with compressed air, but it must be careful not to aim the blast at delicate components like spindles or bearings. Sometimes soaking the tool in a little solvent helps to remove oil and residue; however, generally making sure the tool is completely dry helps avoid corrosion. To preserve the coating and cutting edges of the tool, avoid using harsh chemicals. A clean tool lasts longer, cuts more smoothly, and produces less friction.

Proper storage to prevent damage and corrosion

Boring tool storage must be done properly to prevent rust, damage, and loss of accuracy. In order to keep tools away from other hard surfaces, they should be kept in protective holders. For carbide and high-speed steel (HSS) tools in particular, moisture-induced rusting must be avoided by maintaining a dry, climate-controlled environment. Humidity in storage rooms can be decreased with the use of moisture-absorbing packs or desiccants. Before storing tools for an extended period of time, lightly oil them to add a layer of rust protection. Tools should be arranged according to their size, kind, and intended use to lower the possibility of damage and provide convenient access.

Sharpening techniques to keep cutting edges sharp

Maintaining the effectiveness of boring tools requires regular sharpening because dull edges can result in increased cutting pressures, poor surface smoothness, and even tool breakage. When the cutting edge exhibits wear indicators like chipping, the surface quality becomes less smooth, or the cutting resistance rises, it is time to sharpen the tool. While bigger or complexly geometrized tools are best suited for CNC regrinding, smaller boring tools can be manually sharpened using a honing stone or bench grinder. Diamond grinding wheels are advised for tools with carbide tips to prevent heat damage. Maintaining cutting efficiency and increasing tool longevity are achieved by regular sharpening.

Lubrication to ensure smooth operation

Lubrication plays a vital role in chip evacuation, cooling the cutting region, and lowering friction during boring operations. Making sure the coolant is compatible with the tool and material being machined requires careful selection, regardless of whether it is synthetic, water-soluble, or oil-based. Coolant is directly delivered to the cutting edge by through-tool coolant systems, providing efficient cooling and lubrication. Tool life is increased and lubrication more efficient when coolant levels are routinely checked and the coolant system is kept clean. Longer tool life and smoother operation are the results of proper lubrication, which also lowers heat generation and stops needless wear.

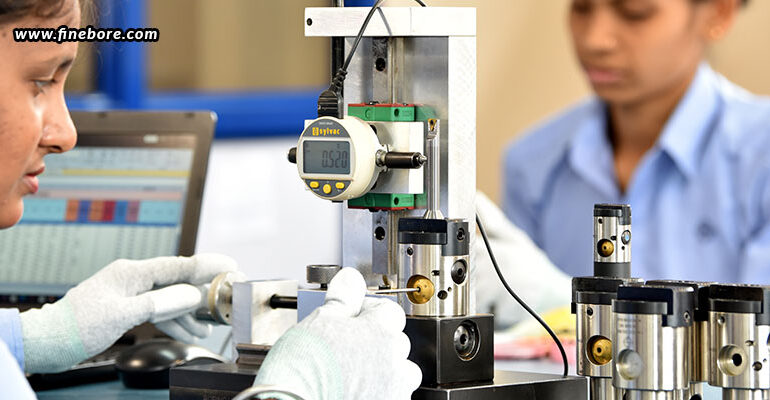

Inspection and replacement to know when to replace components

Boring tools will eventually break or wear out even with proper maintenance. To avoid subpar machining results and significant damage to the tool and machine, it is imperative to know when to change a tool. When a tool’s cutting edge becomes too worn out, chipped, fractured, or loses its ability to maintain tolerances, it should be replaced. The need for frequent sharpening could also be a sign that the tool’s life is coming to an end. Although they endure longer, high-quality tools like CBN or carbide inserts eventually need to be replaced. Before any major problems develop, routine inspections assist in determining whether replacements are necessary.

Preventive maintenance by scheduling regular checks

Regular preventative maintenance inspections can help find and fix boring tool problems before they get worse. Tools stay in peak condition when a maintenance routine for cleaning, lubrication, sharpening, and inspections is established. Predicting maintenance and replacement needs is made easier by keeping track of tool usage based on machining cycles and materials. Regular checks on tool alignment are necessary since misalignment can decrease precision and increase wear. A worn toolholder can have a detrimental effect on performance, thus toolholders and inserts should also be evaluated. Follow a preventive maintenance schedule to extend the life and performance of your boring tools.

Maintaining and caring for boring tools correctly is crucial to getting the most out of them, increasing their life, and guaranteeing accuracy while machining. Every action you take to maintain your tools in top shape matters, from routine cleaning and storage to sharpening methods and replacements on schedule. Preventive maintenance and lubrication help ensure smoother operations and less downtime, therefore they shouldn’t be disregarded. You can preserve the dependability and effectiveness of your boring tools and continue to get excellent results for your machining operations by adhering to these recommended measures. If you’re looking for superior boring tools, consider FineTech Toolings, reputable boring tools suppliers in Bangalore, that can provide you with precisely constructed, long-lasting boring tools that will work for your project.