Home-making takes up most part of the machining operations, wherein a perfect hole is required to be cut into a workpiece. While the most basic process used to cut a hole within a metal is drilling, there are many other processes involved too, in order to make for a perfect finished hole. These include reaming, tapping, and boring. Each process if different, and unique in its own way. We’ll learn more on that later in the blog.

Creating a hole

In machining, a hole is cut from the workpiece by a rotating cutting tool that enters the workpiece axially. The diameter and geometry of this cutting tool will create a hole with the same diameter and geometry. While all machined holes have the same basic form, they can still differ in many ways to best suit a given applications. A machined hole can be characterized by several features or parameters that determine the hole-making operation and tool required.

The diameter

The cutting tools used for hole-making are available in standard sizes, ranging from 0.0019 inches to 3 inches. Fractional sizes, letter sizes, number sizes, and metric sizes are available. The closest standard sized tool should be used, because the diameter of the hole can be determined only by the tool selected.

The depth

The depth of a hole can be determined by the depth to the point, or the depth to the end of the full diameter portion of the hole. The total depth of the hole can be determined by, and is limited to the length of the cutting tool.

The tolerance

This depicts the precision of the hole, which can be affected by a number of factors like the tool’s sharpness, the vibration, and the build-up of chips of material. With some methods being suited for only tight-tolerance holes, the specified tolerance of a hole will determine the method of hole-making used.

The recessed top

Machined holes are generally recessed at the top to accommodate the head of a fastener, allowing it to sit flush with the surface of the workpiece. There are two types of recessed holes – counterbore with a cylindrical recess, and countersink with a cone-shaped recess.

The threads

This is considered when the hole is a threaded one. Such holes are machined with the help of taps and dies, to accommodate a threaded fastener. The pitch is of considerable importance here, which is the measure of spacing between two consecutive threads, which can be expressed as the number of threads per inch (TPI) or the distance in millimeters (mm) between the threads.

Techniques for making holes

As mentioned above, drilling is the most basic procedure for making a hole, but other procedures like reaming, tapping, and boring also exist, to create different types of holes. Let’s learn about each one of these processes in detail.

Drilling

A drill bit is used here to enter the workpiece axially and cut a hole within. The four basic types of drill bits used include twist drill, center drill, spot drill, and tap drill, each beginning a hole, which can be completed further by any other operation mentioned below.

Reaming

A reamer is used to enlarge an existing hole, by removing minimal amount of material, to obtain a more accurate diameter and a smooth internal finish. The flute of a reamer can be straight or in helix, as required by the operation and application.

Tapping

A tap is used here to cut internal threads into an existing hole, which is selected based on the major diameter and pitch of the threaded hole. Threads here may be cut through the entire length of the hole, or only till a specified depth and pitch.

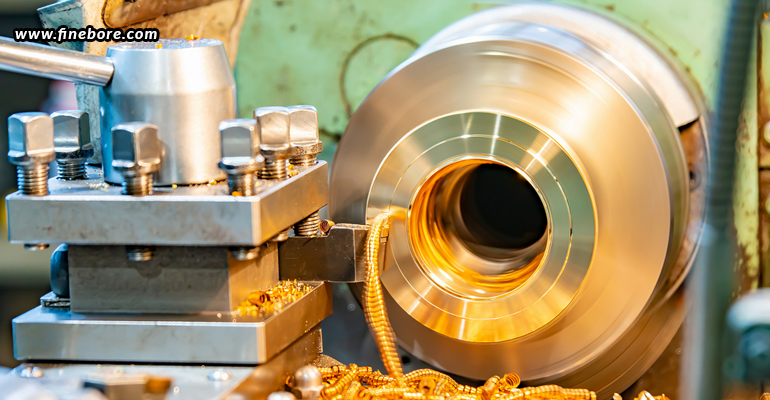

Boring

A boring tool cuts along the internal surface of an existing hole, to enlarge the diameter, or obtain more precise dimensions. This single-point cutting tool can be set to cut the desired diameter, by using an adjustable boring head. Whether a boring bar, or a boring head, or any other boring tool, whatever you need to bore a hole, you can get it all at Finetech Toolings, your one-stop solution for precision boring tools in Bangalore.

Counterboring/countersinking

Counterbore tools or countersink tools are used to enlarge only the top portion of an existing hole to provide space for the head of a fastener, such as a bolt or screw, to sit flush with the surface of the workpiece. The only difference that lies in both the tools is that the counterboring tool has a pilot on the end to guide it straight into the existing hole, and the countersink tool comes with angles of 60, 82, 90, 100, 118, or 120 degrees, as required.